Products

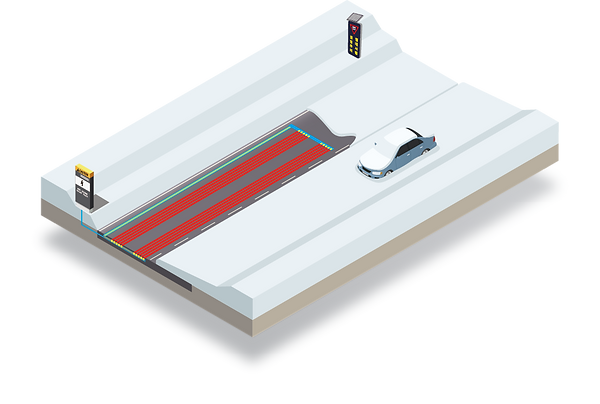

스노우멜팅 시스템 (Snow Melting System)

· A means of securing traffic safety in areas where traffic accidents are expected to occur, such as slopes, curved sections, tunnels, parking lots, underground roads, bridges, etc. during snowfall and freezing in winter.

· An efficient snow removal system that automatically detects temperature, humidity, and snow by burying and constructing a carbon fiber heating line at a certain depth under the pavement to prevent safety accidents occurring in vulnerable points such as freezing on the road surface.

Strengths

01

Finding the starting point of defects for each section, and partial repair is possible, making it easy to maintainable.

02

By applying the SCR system, it maintains uniform electricity supply and stability to the heating wire, thereby prolonging the lifespan of the system.

Carbon heating element cables have high tensile strength compared to nickel chromium wires and are highly durable.

The coefficient of thermal expansion due to heat generation is small, so it is very stable against physical deformation.

Strengths

01

Finding the starting point of defects for each section, and partial repair is possible, making it easy to maintainable.

02

By applying the SCR system, it maintains uniform electricity supply and stability to the heating wire, thereby prolonging the lifespan of the system.

03

Carbon heating element cables have high tensile strength compared to nickel chromium wires and are highly durable.

04

The coefficient of thermal expansion due to heat generation is small, so it is very stable against physical deformation.

05

When the road contracts, expands, or heats up, a short circuit does not occur due to vibration.

06

It has strong corrosion due to oxidation, so it can be used semi-permanently.

07

Maximize the melting effect by increasing the concentration and efficiency of heat conduction by using AL cap.

08

The most suitable product in the smart era by applying and operating a remote control system (IoT).

09

Real-time monitoring of installed products using LTE network and establishment of a remote control central management system.

The structure of the product

2

3

4

1

2

Connection part

The connection part between the heating wire and the general wire.

2nd round of waterproofing using the water shrink tube.

1

Power distribution box/control box

A system that controls input/output.

4

Driver's freezing forecast sign

When the freezing condition is reached, a warning is displayed on the power standalone forecast sign through the wireless (RF method) module to forecast a risk to forecast to the driver.

3

Carbon fiber heating wire

It has moderate flexibility, heat resistance, water resistance, alkali resistance, and oil resistance according to the strength and vibration that can withstand the load of the vehicle.

Pavement method: Cut the existing road and repackage it

Anti-slip packaging: Cutting method

Details of carbon fiber heating wire

AL Alloy Casing: Before operation

AL alloy casing worn: After operation

· Using a stripping sleeve for connecting the carbon fiber heating wire and the wire (*Patented technology for compressing while maintaining a constant density of the carbon bundle)

· Maintaining constant density and compressing carbon bundles minimize heat transfer losses and reduce electricity bills.

IoT Remote Control Smart System

· Automatic detection sensor is used to collect the condition of the ground at all times, and based on this, automatic on/off.

· Automatic ON/OFF based on the ambient temperature and the set timer setting.

· Data collected using automatic detection sensors can be transmitted to the administrator's computer and managed remotely.

· The manager's computer can remotely control snow melting, whether there is a fault, location of failure, appropriate

temperature control according to snowfall, ON/OFF control, etc.

Construction procedure

01

Grooving

02

Heat wire and AL casing

03

AL casing grooving groove insertion

04

Connection of hot wire and wire

Before and after construction

05

Piping for wires

06

Recharging mortar

07

Power transfer and wrap up

08

Wrap-up closing

Before snow-melting

After snow-melting